About us

Company History

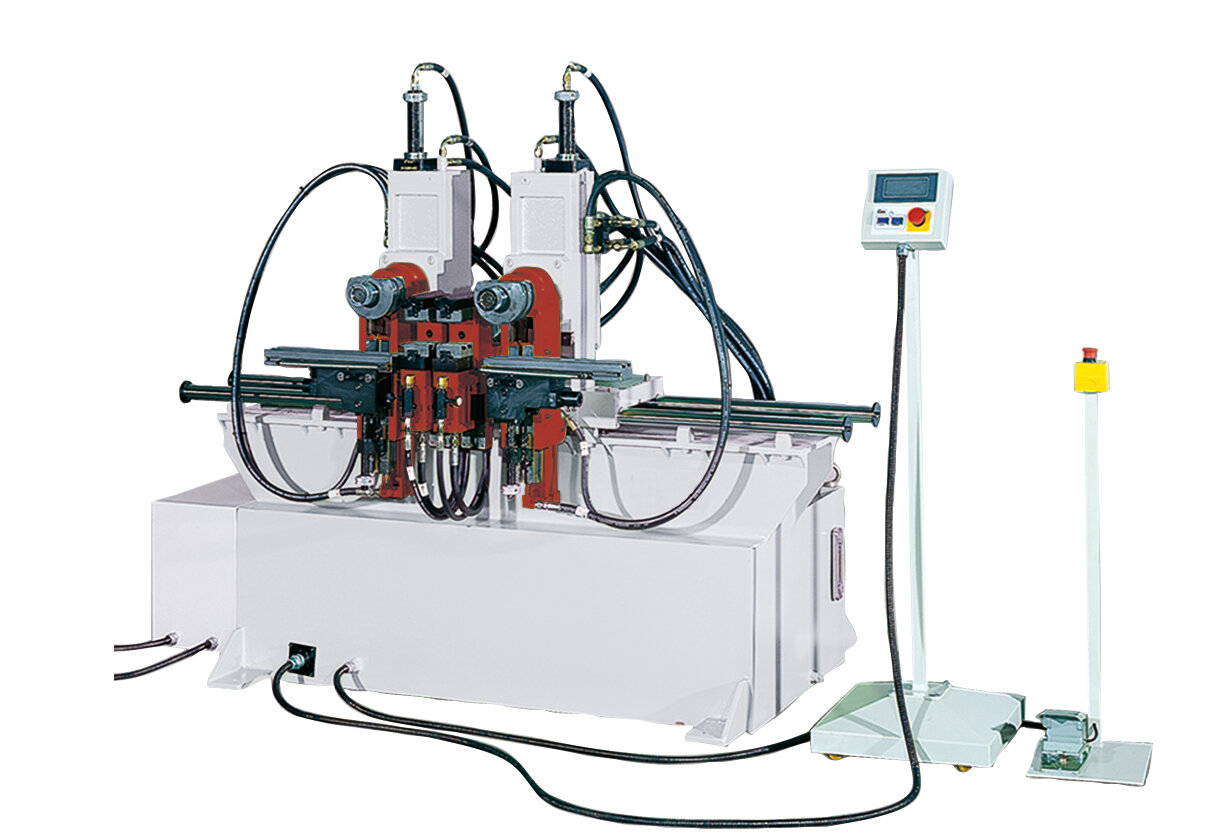

Established in 1981, our design and engineering team serves a broad industrial spectrum, including: automotive, motorcycle, marine, heating and air conditioning, medical, furniture, and bicycle markets.

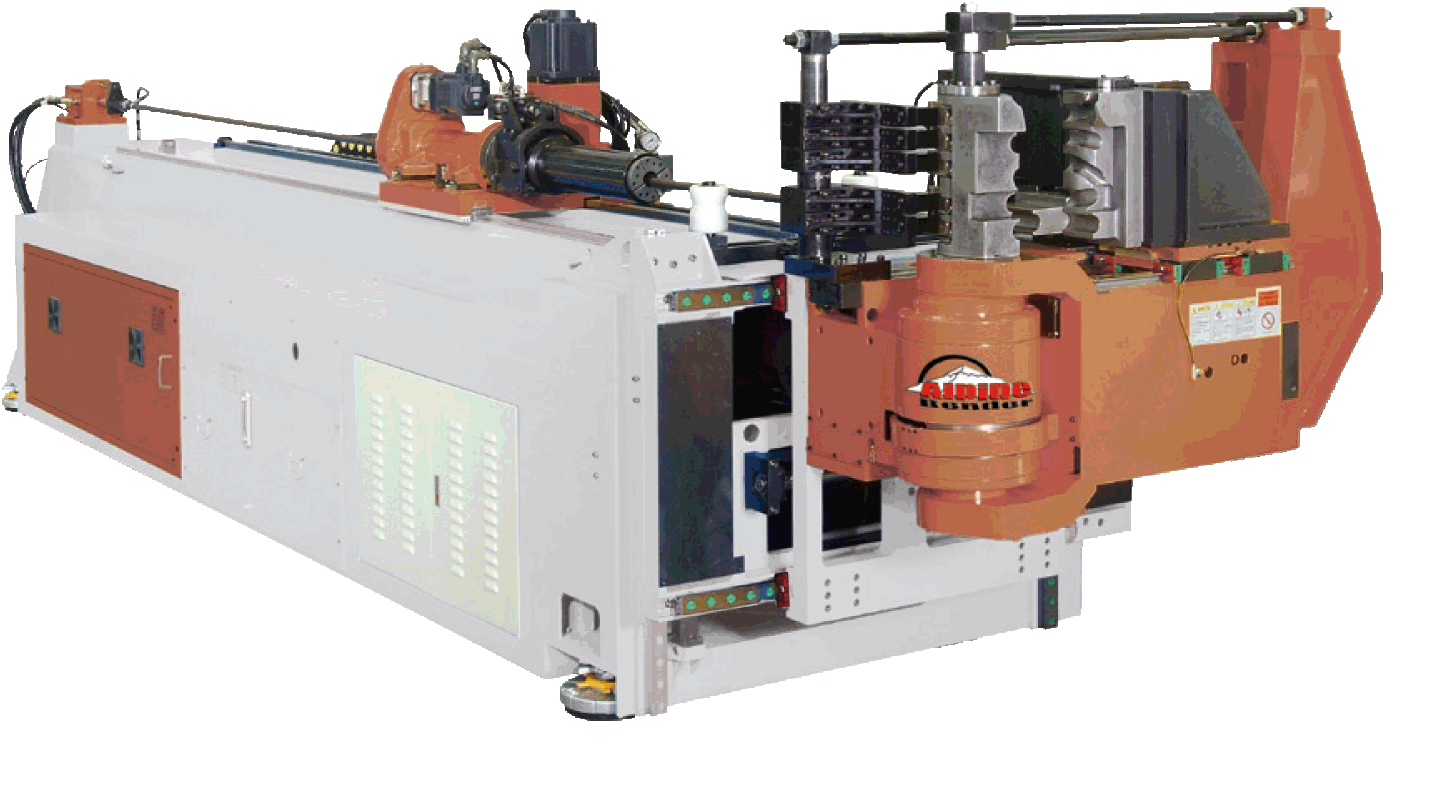

1999 Introduction of CNC tube bending machinery to USA market

2000 First electric hybrid tube bender introduced

2003 First double stack electric hybrid tube bender introduced, equipped with planetary bend head with bending & rolling capability

2004 First electric-driven high torque booster (RBE) introduced

2005 All electric CNC Bender (12 axis) introduced

2007 All-electric model capable to bend from Left and Right (14 axis) introduced

2009 Alpine Bender establishes its service centers and dealers across the USA

2011 Alpine Bender increases global distribution in North America, South America, Europe, and Asia

2012 Alpine Bender offers complete automation bending cell and bender software intergrades with uncoil system, straightening device, autoloader, robot, and portable CMM

2013 Alpine introduces dynamic Master 4 Control featuring Real-time PLC program modification

2014 Automatic work cell with integration of robotic loading and customized drop off system

2017 Alpine introduces M5 (5th generation) control software with real-time motion modification

2019 Alpine introduces upgrade version of B5 (Beckoff PLC) control system

2021 Alpine introduces optical fiber tube laser cutting system

Alpine Bender continually strives to excel in offering the latest innovations in tube bending machines with excellent quality, while fulfilling the service, parts, and technical needs of our customers throughout the United States, Mexico, and Canada.

Alpine Featuring

OEM by world class manufacturing facility with annual production of over 500 CNC units per year. By far the highest volume manufacturer of related CNC tube bending equipment in the world.

Manufactured more than 10,000 units since 1985 for worldwide consumption.

All electrical components meet CE standard and easily sourced in USA.

pneumatic and hydraulic components with NFPA fittings for easy cross referencing with major brands.

Wide range of Model selections and machine capacity (up to 10” OD)

Worldwide patented advance bender technology

Newly develop user friendly multi-purpose Master IV Controller

Fully supported by Alpine Authorized distributors for installation, training, and service

Thorough machine evaluation and consulting available per customer application